WORLD-CLASS PROJECT ADOPTED TO OUR COMMUNITY

clean energy for the future of mankind

The Project

AGA’s Green Ammonia Production Facility (the “Project”) comprises the design, development, financing, construction, ownership, and operation of an integrated process Facility in Australia’s Northern Territory with a commercial quantity processing capacity.

WORLD-CLASS PROJECT ADOPTED TO OUR COMMUNITY

The Green Hydrogen/Ammonia produced can be applied in diverse uses, mainly in the hard-to-abate sectors (industry and mobility), helping the country’s decarbonization journey and showcasing Australia’s true green potential to the world. The Green Hydrogen produced will be used as a Feedstock in producing the Green Ammonia as a final product.

lANDMARK PROJECT FOR THE PLANET

The energy we'll need for the future

Green Hydrogen

GREEN HYDROGEN is the world’s most abundant and lightest element and is made from electrolysis to split water into hydrogen and oxygen using electricity from renewable energy. Green Hydrogen is emissions-free and has many industrial applications, from refining to petrochemicals to steel manufacturing and the mobility sector.

Green ammonia

GREEN AMMONIA is a pungent gas widely used to make agricultural fertilizers and many industries including power generation. Green Ammonia production involves a process that is 100% renewable and carbon-free. The production of green ammonia could offer further options in the transition to net-zero carbon dioxide emissions.

COMMERCIALLY - PROVEN

Process Technology

ALLIED GREEN AMMONIA (AGA) is blazing the trail to a Green Ammonia economy in Australia’s Northern Territory. AGA is in an advanced stage of developing its commercial-scale production facility to produce Green Ammonia. Green Ammonia is a carbon-free fuel made from water by using renewably produced electricity to split hydrogen molecules from oxygen molecules. Our chosen technology is commercially proven.

Premium Banner

Premium Banner

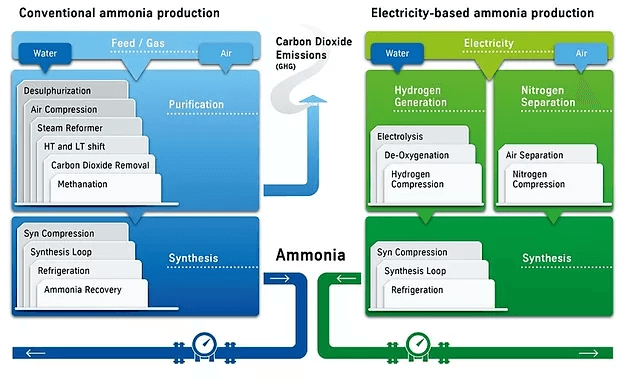

Differences between conventional and green ammonia production

the colors of HYDROGEN

About Gray Hydrogen

Gray hydrogen is derived from natural gas and produced from fossil fuels, making it a minor renewable form of hydrogen. Most of the hydrogen produced today is gray hydrogen. It is relatively inexpensive and commonly used to make fertilizer and refine oil in the chemical industry.

Gray hydrogen is produced by reforming natural gas, a processing technique used to rearrange the molecular structure of hydrocarbons. In this process, methane, the primary element in natural gas, is mixed with steam at a high temperature to yield hydrogen and carbon dioxide through a catalytic chemical reaction.

Unfortunately, almost 10 kg of carbon dioxide is released into the atmosphere for every 1 kg of gray hydrogen produced. This high ratio of CO2 generation gives this form of hydrogen its “gray” designation.

Gray hydrogen is viewed as a “bridging” energy alternative as the world weans off fossil fuels. But its impact on climate is negative overall, much like drilling for oil or mining coal.

About Blue Hydrogen

The same chemical processing technique used to make gray hydrogen also produces blue hydrogen. The big difference, however, is the management of CO2. With blue hydrogen, the CO2 produced does not escape into the environment. Instead, it is captured at the production facility and stored separately. This technology is known as Carbon Capture and Storage (CCS). However, storage is costly and has logistical challenges.

Blue hydrogen is currently attracting attention as a realistic alternative because it has a significantly lower CO2 impact on the environment than gray hydrogen, making it more sustainable overall. However, the blue hydrogen process does not eliminate carbon emissions into the atmosphere entirely. It may be more ecologically friendly than gray hydrogen but is by no means perfect.

About Green Hydrogen

Closer to real sustainability is green hydrogen, the new kid in the block. This form of hydrogen follows an entirely different production process than that of gray or blue hydrogen. The electrolysis technique separates hydrogen and oxygen molecules by applying renewable electrical energy to water. Renewable sources such as wind, hydro, and solar power generate electricity for this process.

Utilizing renewable sources instead of fossil fuels is the key to making green hydrogen. This technique yields a closed-loop of sustainable energy in which no harmful gases come into existence at any point in the production chain, making it the ultimate goal in the hydrogen fuel space.

Although green hydrogen appears to be the ideal choice for mobility and other applications, producing it presents specific challenges. The machines used to carry out electrolysis are costly. Furthermore, clean electricity from solar and wind sources is limited in supply. The environmental advantages of green hydrogen are potentially far-reaching, but advancement to producing this clean energy source will become practical soon.

In the Spotlight

AGA has a bold ambition and long-term vision of producing a sustainable GREEN AMMONIA without affecting the environment. We identify, invest, and develop environmentally, economically, and socially sustainable Green Ammonia to sustain our long-term requirements and future expansion.

alfred benedict

Chairman & Managing Director

The Future of Green ammonia

Green Ammonia, which uses renewable energy to produce Green Ammonia from water, is taking off around the globe. Green Ammonia Fuel plays a vital role in decarbonizing hard-to-electrify sectors of the economy, such as long-haul trucking, aviation, shipping, and heavy industries.